Regenerative Turbine Pumps

Dependable Performance for Low Flow High Head Applications

G Squared is proud to offer Roth regenerative turbine chemical duty pumps. These regenerative turbine pumps provide continuous, high-pressure pumping of non-lubricating and corrosive liquids. The pumps are provided with one piece, machined self-centering impellers for operation with a wide variety of chemicals with process heads up to 1400 ft.

- Offers the performance of a multi-stage centrifugal pump with a single turbine impeller running at low speeds

- Guaranteed performance at 1 Foot NPSHa process conditions

- High head, low flow pump can handle entrained bubbles without vapor locking pump

- Reliability for lowest cost of ownership, less downtime

- Performance matched to your unique pumping challenges (sub-ANSI design, Low NPSH)

A broad variety of mechanical seals are available, and front pull-out makes pump seal maintenance simple and straightforward.

G Squared Supplies Regenerative Turbine Pump Needs in the Gulf Coast Region

We partner with Roth Pump to offer you the industry’s top performing regenerative turbine pumps. As your Gulf Coast process equipment specialist, G Squared offers you many advantages:

- Custom engineering and fabrication to meet specific needs

- Knowledgeable and responsive customer service

- Experienced OEM & CEM support

- Quick lead time and fast delivery

- Expedited shipping available

Our team offers you the best combination of performance, quality, and value to assure the long-term efficiency and reliability of your process. Contact G Squared to discuss your regenerative turbine pump needs.

-

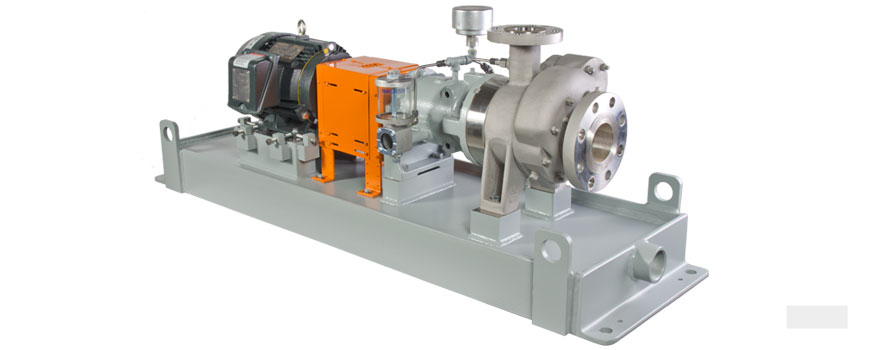

Roth Regenerative Turbine Chemical Pump

- Specifications

- Features

- Applications

- Process heads up to 1400 ft. (427 m.) TDH at 3500 rpm

- 600 psi (40 bar

- NPSH from 1 to 14 ft. (0.91 to 4.2 m.)

- Temperatures to 450°F (232°C)

- Capacity 100 GPM (22.7 m3/hr)

- Develop higher pressures

- Can be run at lower motor speeds

- Eliminate cavitation

- Operate with lower NPSHr

- Deliver specified capacity with input pressure variations

- Meet performance with fewer stages

- Smaller size

- Available in mag drive design

- Offshore Oil Platforms

- Refineries

- Chemical and PetroChemical Plants