Combustible Dust and Wet Dust Collection

A discussion of basic dust collection would not be complete without discussing the issue of combustible dust. Also referred to as explosive dusts, combustible dusts must be managed with special consideration given to safety. After years of inadequate consideration, combustible dust is finally being addressed seriously through updated codes and standards, legislation, regulation, and enforcement. It is now imperative that any manufacturing operation address and deal effectively with the problem of dust explosions.

For processes involving explosive dust, as well as sticky, oily, or hygroscopic dusts, wet dust collectors are typically the best option. Wet dust collection is also well-suited for high temperature and high moisture air stream applications. Not only do wet dust collectors safely handle these tough applications, they eliminate the factors that cause dust explosions.

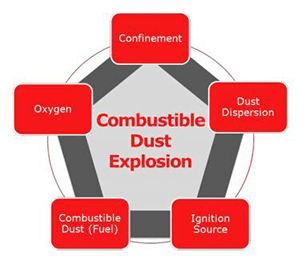

In order for a dust explosion to occur, the following five factors must be present:

- Fuel – dust particles

- Dispersion – a dust cloud of fuel (often produced when a dry filter is pulsed clean)

- Oxygen – supplied by the surrounding air

- Confinement – the dust cloud is trapped (can be within the dust collector)

- Ignition Source – such as a spark generated by friction

By design, a wet dust collector separates dust from an airstream, which eliminates a number of the factors that cause dust explosions. Air containing dust enters a wet collector and through a combination of induced aerodynamic and hydrostatic forces. The dust in the air is “wetted” and transferred from the air to the water. In the case of an explosive dust this achieves three critical objectives:

- The transfer of the dust from the air removes it from an oxygen rich environment. Without oxygen combustion cannot occur.

- The use of water eliminates any potential source of combustion. This also eliminates the need for spark detection and extinguishing systems.

- Since the dust has been eliminated from the air and is now in a “wetted” state, there is no mechanism by which a dispersed dust cloud can form.

The wet dust collection system design is similar to dry dust collectors, but when handling explosive dusts, there are other design requirements that need to addressed. The duct work must be appropriately designed for explosive dust collection and the collector needs to be bonded/grounded. The NFPA, or National Fire Protection Association, has several codes that relate to safely collecting combustible dusts, such as NFPA 484 Standard for Combustible Metals.

For more information on how to meet NFPA 484, please feel free to contact us. Wet dust collector designs vary by manufacturer, and not all wet dust collectors design are equal. If you have an application that may be a good fit for a wet dust collector, contact us to review your options.